Free Standard shipping on orders over £50 + VAT on orders placed before Midday.

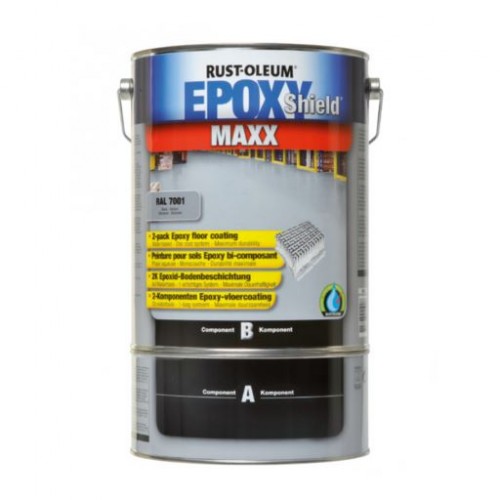

Rust-Oleum 5300 Epoxyshield Maxx 5L

Rust-Oleum 5300 Epoxyshield Maxx is a 5 litre, gloss finish, water-based 2-component epoxy concrete floor coating with ultimate adhesion and durability on concrete.

Part of the Epoxyshield range

- Maximum durability in just 1 coat

- For medium to heavy traffic

- Best possible car tyre resistance

- Easy to apply, no primer required

£90.42+ VAT

- Product Code: 5381 / 5382

- Brand: Rust-Oleum

- Availability: In Stock

Rust-Oleum 5300 Epoxyshield Maxx

A user friendly and easy to apply water-based 2 component epoxy floor coating with an ultimate adhesion and durability.

- Maximum durability in just 1 coat

- For medium to heavy traffic

- Easy to apply, no primer required

- Long-lasting gloss finish

- Best possible car tyre resistance

- Highly resistant against solvents and chemicals

- Non-skid or decorative finish optional

The product has an excellent wear, impact and abrasion resistance like foot and vehicle traffic. Resists chemicals and standing water. The product can be applied on concrete floors, which are completely clean and dry. It is not recommended to apply on smooth/dense concrete or concrete containing a curing compound, which will prevent a good adhesion. Can also be applied on old good adhering coatings.

Recommended Use

Epoxyshield 5300 MAXX can be applied on concrete floors, which are completely clean and dry. It is not recommended to apply on smooth/dense concrete or concrete containing a curing compound, which will prevent a good adhesion. Epoxyshield 5300 MAXX can also be applied on old good adhering coatings. Epoxyshield 5300 MAXX Additives:

Technical Data

- Density: 1,27

- Gloss Level: Satin

- Solids content in volume: 63.6%

- Mixing Ratio: Base : Activator = 3 : 1 (volume)

Drying Times At 20°C/RH 50%

- Dry To Handle: 16 hours (suitable for light foot traffic)

- Dry To Recoat: 24 hours (suitable for normal foot traffic and heavy items)

- Fully Cured: 7 days (suitable for vehicle traffic)

- Pot Life: 2 hours (15°C), 1½ hours (21°C), 1 hours (26°C)

- Induction Time: Brushing: 30 minutes (15°C), 10 minutes (20°C), Direct (25°C). Rolling: 45 minutes (15°C), 15 minutes (20°C), 5 - 15 minutes (25°C)

Directions for Use

Pour the contents of A into B and stir thoroughly for at least 3 minutes. Allow mixed product to stand (see table) before rolling the coating on to the surface. Do not leave container in direct sunlight. Mix again before applying. The product must be used within 1 to 2 hours of initial mixing (pot life, see table). This time decreases at higher temperatures. Do not mix Paint Chips with Epoxyshield 5300 MAXX.

Application Conditions

Apply when air (ambient) temperature is 15-35ºC and relative humidity is below 80%.

Concrete floors take a long time to warm up; make sure the previous day has also been at least 15ºC prior to painting. Minimum floor temperature for painting is 13ºC. Painting in mid afternoon ensures the best cure.

Application and Thinning: Roller

After the full 60 minutes use a paint roller (20 cm) to apply an even coat of Epoxyshield 5300 MAXX onto the surface. Apply in sections of 1,5 x 1,5 m so that Epoxyshield

Decorative Chips can easily be scattered on the freshly coated surface. Maintain a wet edge to prevent lap marks and gloss differences. Sprinkle the decorative paint chips onto the wet film (note: this step may be skipped if chips are not desired. This will not affect the performance of the coating). Immediately continue to coat the next section (note: fresh paint can be applied over the loose chips that lay outside the previously painted area). Only one coat is necessary.

Cleaning of Equipment / Spills

Wash all tools and equipment immediately with warm water and mild detergent. Allow any unused product to harden in the container and discard according to local regulations.

Remarks

Since the application time is only 1 - 2 hours (depending on temperature) it is advisable to apply the product with 2 persons. Have 1 person begin trimming edges and have another person begin rolling out the floor as specified.

Sealed concrete: dripping a small amount of water onto the surface. If the water beads, a sealer is present and paint may not adhere properly.

Moisture in the concrete: apply a sheet of plastic (e.g. garbage bag) to the floor. Tape down the edges and allow to set for 24 hours. If water droplets appear on the inside of the plastic or if concrete appears wet (darker in colour), moisture is trapped in the concrete.

Loose concrete or concrete dust: if the concrete is loose, chipping or has concrete dust present, the coating will not perform properly unless all loose material and dust is removed and damaged areas are repaired.

Floors treated with a levelling mortar or on anhydride floors.